Robots And Different Types Of Industrial Robots

Robotics is a different branch of engineering and science. To develop robots we use some technology like mechanical engineering, computer science & engineering, electronic engineering. Thus we can say robotics is a collection of different technology. Development of the robot to a good achievement for the human.

History of Robots

History of robots inspiration an age-old world. Develop a modern concept with also develop industrial revolution that flows a new direction which developed a machine and motor which to give a power used the electric city. 20 century ago develop was a humanoid machine. The first time to use robot purposes for industrial which known as an industrial robot. Using an artificial intelligence was developed robot has been built the 2000s.

1. The father of robotics is “Georges Charles Devol” developed the first industrial robots that are “Unimate” in 1954.

2. First prototype robot developed in 1964 which manufacturing cost was ”$65000” and it sold by $81000.

The main type of robot

In present human had been developed many types of robot. We will describe here some specific type of robots. Mainly described the robot that made of for industrials purpose. Use of industry there is six type of robot are available. Which are defined below one by one.

Some type of industrials robots

1. Articulated robot

2. Delta robot

3. Cylindrical robot

4. Cartesian robot

5. Polar robot

6. SCARA robot

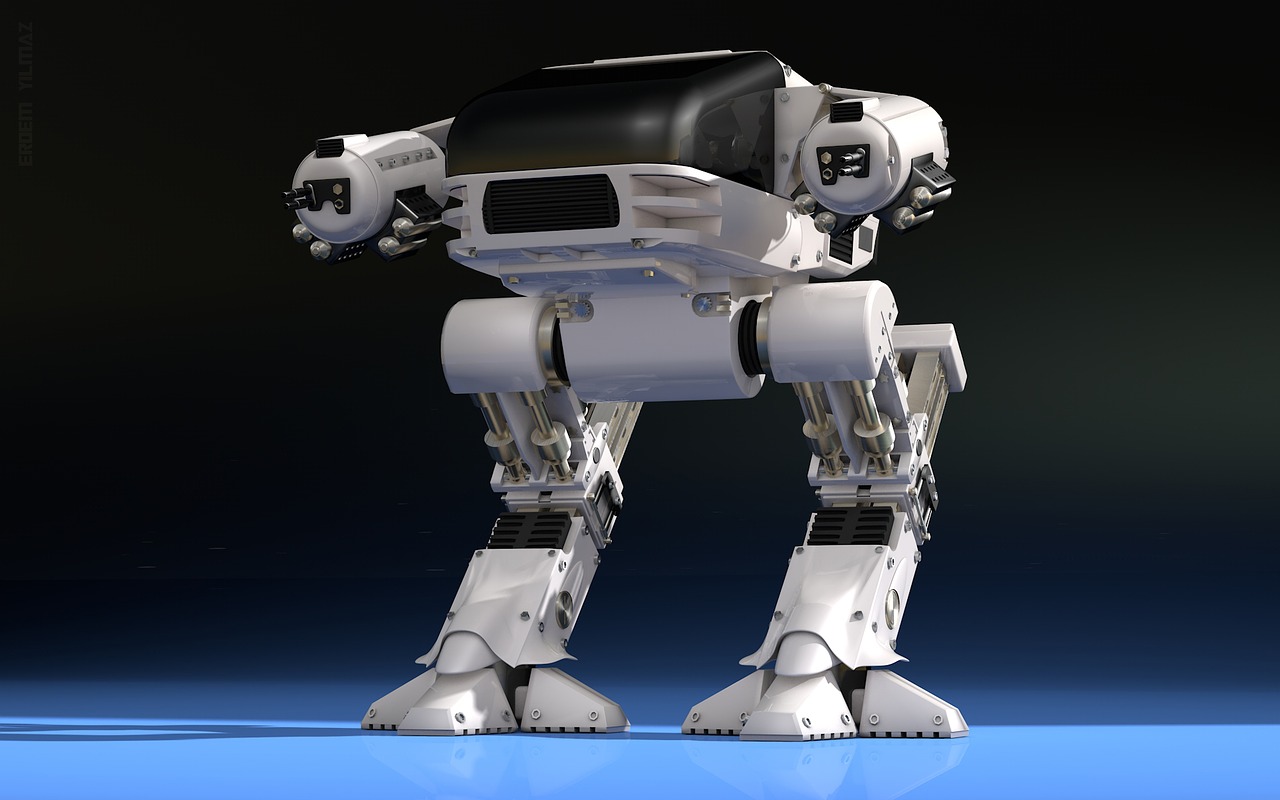

Articulated robots

Articulated robots have a rotational joint. It’s structure created by the human which may be 2 or maximum 10 joint. The arm is joined in rotation point that can move around all side. Join is called axis point. An industrial robot has minimum joint 4 and maximum of 6 axes.

How to Articulated robots work

on his axis- it has 6 axis point to work.

Sr No | The working point on the Axis |

1. | Rotates on the robot (it is a base on the robot) |

2. | Use for backward and forward robot lower arms |

3. | Raises lower robot’s upper arm |

4. | To rotate robot’s upper arm |

5. | Raises for lower robot arm (wrist) |

6. | Use it rotates for robot’s rest |

Delta robots

Delta robots are also known as “spider robots”. These types of the robot are made of jointed parallelograms on a common base. Parallelograms are demo shape area like as circular. Maximum use of this robot is in food and electronics industry. It is most useful for human and industry.

1. Delta robot was developed by professor Reymond Clavel in 1980.

2. It is very fast and used to industrial purpose delta robot 300 picks in per minute.

3. Delta robot’s 30% faster than “SCARA robots”.

4. Delta robots are most perfect for assembly purpose.

Cylindrical robots

The configuration of the cylindrical robot has at least one rotary joint on base and one linear joint attack on the base. Rotary joint provides motion all side and liner joint to use move liner side. It is used for assembling operation like as spot welding. Cylindrical robot arm defines different parameters.

A number of axes: Cylindrical robots have only two axes from working.

Speed: It speeds id define by angular and linear movement.

Motion control: Motion control is very accurate because of use for a certain application that works on the required point.

Power source: For power source used electric motors and hydraulic.

Drive: A motors hooded attached for a directive drive or hydraulic drive system.

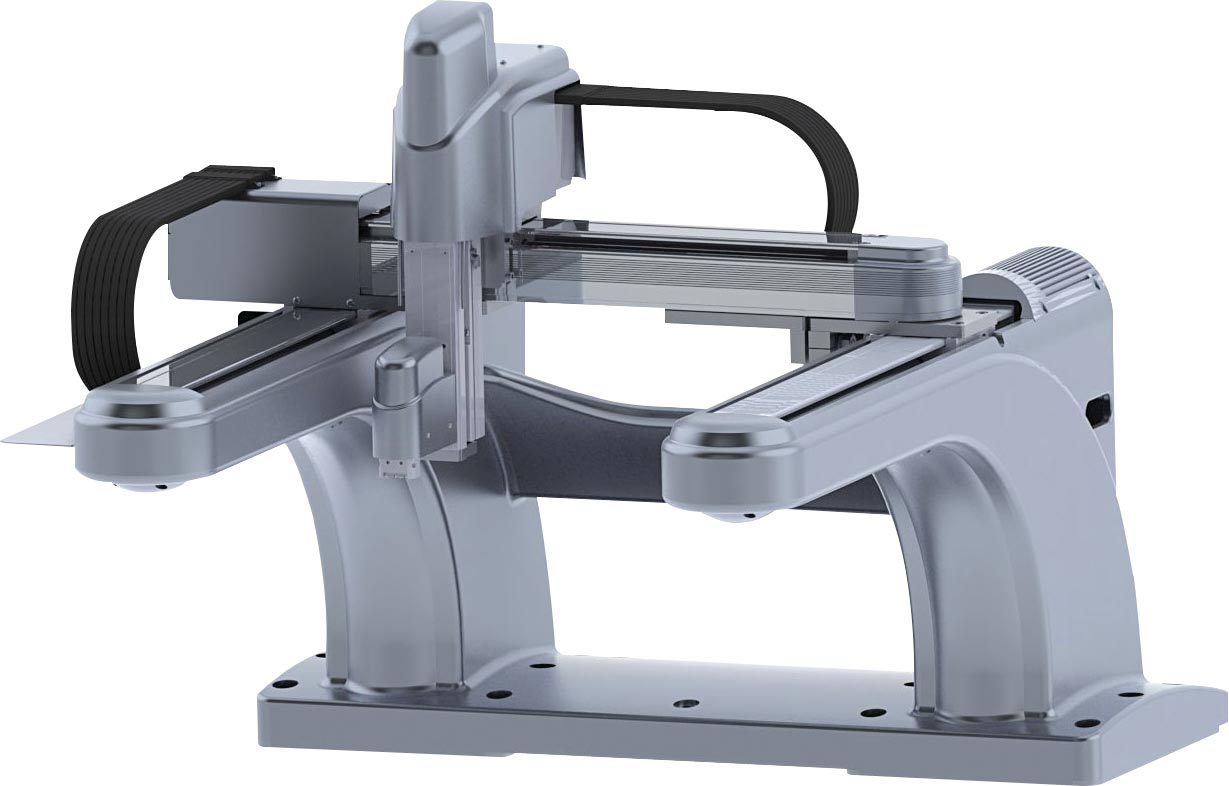

Cartesian robots

It is a gantry robot. Cartesian robots have three linear joints for the Cartesian coordinate system. Cartesian coordinates means three-dimensional axis like(x,y,z). This point connects a single rotational point and it moves around liner motion.

Polar robots

We also know it spherical robots. A polar robot is configuring by arm connected in twisting joint. This joint is rotational and one linear joint. Coordinate of axis point create a spherical shape for the work envelope.

1. The polar robot was developed by Victor Scheinman in 1969.

2. These are creating by animate puma company use for industry.

3. Polar robots have a robotic arm that uses for many purposes like as gas welding, fitting, spot welding etc.

4. Maximum use of the polar robot is in a simple task.

SCARA robots

Scara robots structure like as cylindrical edging. It is commonly used for assembly application. Scara have two parallel joints that provide observance in the selected plan. it arms joint configuration like human arms. Cartesian robots are slower than scara.

How it works

1. Scara robot manipulates to work degree freedom.

2. Maximum use for scare robots to pick things to place one place to another place. In present time extraordinary use for scare robot-like as manufacturing field, electric field etc. Arm structure of scara robot shoulder and elbow is moving on vertically also wrist vertically.

The advantages of the robots

Most people have bad thoughts about robots, they think that robots are built with full automation techniques and they will take away your jobs after a few years. Nothing of the sort, because Robots will make easy your work and provides more facility at your workplace. With the help of robots definitely, you can increase the work efficiency of your company. I am going to explain some important benefits of robots that will fully change your thinking about robots.

1. Productivity

2. protection

3. Saving

4. Fastly work efficiency

Productivity

1. Its work is very accurate and high quality.

2. The work mistake chances are very low in the compare to human work.

3. Robotic work is very fast in a short amount of time.

4. Robot work all day without a required holiday.

Protection

1. The robot can do safely in the dangerous task.

2. Robotic work is accurate he will know easily wasted material campaign to human.

Saving

Robotic work safe a large amount of human time without mistake.

Fastly work effiency

During work, robots do not be worried nor need to take rest. Robots can work for 24 hours in a row and they do not need a vacation like humans. Apart from this, robots can do your work at the same speed as long as your work is not finished while it is not possible by human because human not be made of any technology, It is fully natural which created by God. Robots do not need to eat foods nor they tire therefore they can work fastly and their work productivity and efficiency better than human.

Proficiency

Robots will work always quality because the robot is fully programmed therefor It has less likely to make mistake chances. While during the work human has more chance to make an error. therefore robots make perfection product every time.

Job creation

Robots will not take the job away from people while completely change the jobs that exist. Robots require people for monitoring and administration. The further robots we demand, the more people we’ll require to build those robots. By raising your employees to operate with robots, you’re providing them a reason to stay stimulated in their position with your company. They’ll be beyond for the improvements and they’ll have the unique chance to develop a new set of tech or engineering-related professions.

The disadvantage of robotic

Cost:

Cost of a robot is very high and it is not affordable for every company owner.

Identify our need

If we need a robot first we will understand robotic programming and robotic designing than a robot work perfectly for our company.

Conclusion

Above we describe all the thing about the robot and its function. To seeing science and technology our modern time will be robotic. And we can see everywhere robot-like as factory, industry, and company etc. invention of a robot will be which create a critical condition to unemployment. But I, at last, tell you that the work time of human-less and machine working time is increasing trend. Human will do our work very easily.