Difference Between belt drive Vs chain drive

The most common topics the bikers are discussing that which is better between Chain Drive and Belt Drive. But the majority prefers the chain Drive. It is the most common system and best among all three. Both Chain Drive and Belt drive are a part of a mechanism that allows the motion in the bike and transfers power in particular machinery.

The Belt drive and chain drive is an aid to transfer the power to move objects like hoisting and conveying etc. Chain drive and Belt drive are in many vehicles (like bicycle, bike, automobile) and many more as well as other mechanical application like garage doors, etc. The chain drive and Belt drive are designed to continue and endless loop working to provide the engine is running.

And today we are going to discuss which is better belt drive or chain drive, and why bikers prefer chain drive over the Belt drive system.

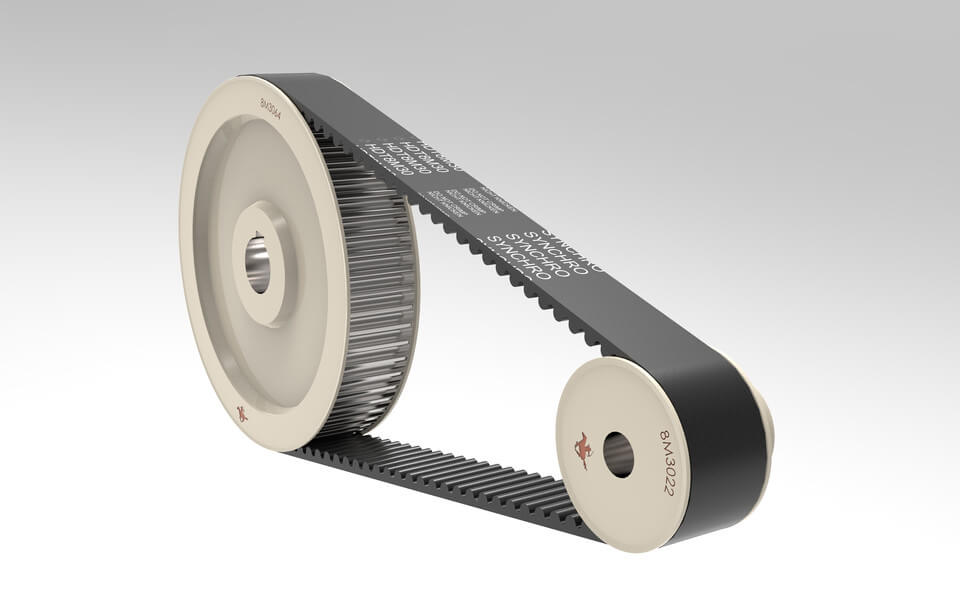

Belt Drive

The Belt drive made up of Rubber, Plastic, Synthetic substance and many other things. The Belt drive is a smooth and wide span due to the synthetic material. A Belt drive is best to utilize for machines and is exceptionally valuable in an examination for harm or wear. The outside of the Belt can all the more effectively show proof of the referenced blemishes and can be a sign that acquiring a substitution might be necessary.

Another preferred position of the Belt drive is that it requires fewer alterations and is calmer, cleaner, and runs all the more easily contrasted with the chain drive. This kind of drive doesn’t require grease, which can be considered as an additional expense to a machine’s support. The terrible thing about Belt drives is the way that they frequently lapse prior contrasted with the chain drive.

Belt drives can likewise slip or snap if the belt isn’t kept up or possibly unmaintained or indications of harm and wear. The Belt drive intervals are 25,000 to 35,000 kilometers, unlike the chain drive which they need cleaning, greasing and checking every 800 kilometers. The kevlar reinforced Belt lasted up to 60,000 to 90,000 kilometer or maybe more.

Belt Drive is smoother in the activity and doesn’t require oil or grease for smoother running. There is one condition that chain drive cannot be cut or harmed while the Belt can be harmed due to weather or climate conditions and they can be a minor effect. Furthermore, Belts are not very great with stress board while the chain can rule in that. This is a central motivation for why performance-based cruisers do not drive Belts. Maybe as a pioneer in innovation these days, the Belt drive is improved and made of more grounded material to resist cuts and damage.

There is a list of types of belts which include flat belt, vee belts, multi belts, round belts, film belts, ribbed belts, endless belts, metal belts, specialty belts.

Maintenance Efforts – Nil

Cost of Maintenance – Low

Cost of Replacement – High

Advantages & Disadvantages of Belt Drives:

Cons:

- Slipping problem.

- Low power output.

- Can be scratch easily

Pros:

- Smoother operation.

- No lubrication required.

- Longer life

- Highly efficient.

- Shock absorption capabilities.

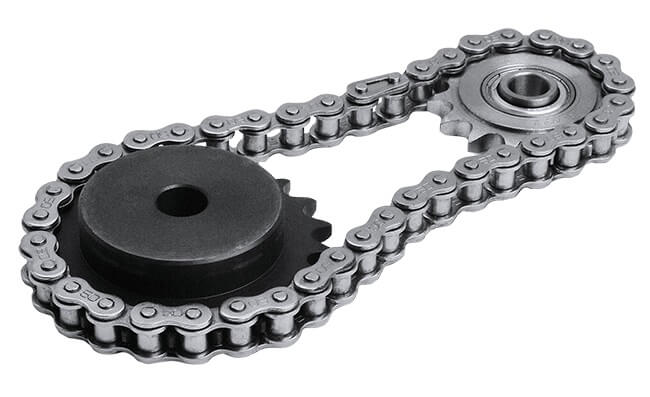

Chain Drive

As the name says the Chain drive is made up of Chains with the special structure like teeth one side and corresponding etch on the other side. The chain drive works with the two side link together which provide the movements of the chain as well as power. The design and structure also allow the chain to keep the hold one place in one direction. The chain drive is stronger and durable because they are made of metal. It is also more dependable to use and easier to repair.

A Chain drive is used in almost all the bikes that you see on a daily basis in our life because it’s reliable and cheap to maintain. It is true they need maintenance from time to time. A chain system needs to be cleaning and lubricant after every gap of 500 to 800 kilometer to protect the chain from getting dirty and rusty and dysfunctional. If the Chain gets gag and dirties it will lower the life of the chain that means it won’t last 20,000 kilometers.

If you do proper care of the chain it will last long to 40,000 to 45,000 kilometer depending on the ride of your bike and how you take care of it. A chain drive is an advantage in almost all the super sports bikes because the fact is the power loss percentage in the chain is little as almost 3%. Also, the chain is capable sufficient to deal with the high power of torque which is given by the machine, and most important that all the dirt bike and drag races bikes value in a chain-drive mechanism. Chains are also handling in many other industries such as Military purpose for (TANKS) and in the mining industry.

The wheel of the Chain-drive mechanism requires alignment, unlike shaft-driven systems, and if the chain sprocket chews the tooth or breaks accidentally, it can result in rear-wheel lock-up and this gives you a real will stand for a screw. The order for a Chain drive is as per the following: roller chain, twofold pitch roller chain, quiet (transformed tooth) Chain, separable connection Chain, and designing steel chain. There are likewise three sorts of burden grouping for chain drives: smooth burden, moderate stun burden, and overwhelming stun load.

We can say that Chain drive is better and more preferable than Belt drive. There is a reason why it is better because Chain drive is joint via links to each other and there is no chance of slipping and power loss during the operation metal chain are more durable and power delivery is smooth. In vehicles where big performance needs like Bikes where the power transmission is very high, that is why we need chain Drive to handle it.

Maintenance Efforts – Very High

Cost of Maintenance – Medium

Cost of Replacement – Low

Advantages & Disadvantages of Chain Drives:

Cons:

- Require lubrication.

- Tough to avoid rusting.

Pros:

- Made of metal.

- Cheap in cost.

- Simple operation.

- Lightweight.

- Can handle higher stress.

- High power transmission efficiency.

- No chance of slip.

Conclusion

We can say that both are handling in the drive system which is good but somehow 90% of two-wheelers use Chain drive for the power due to strength and capabilities. But I think Belt drives are still developing and we hope in the future we can see the new evolution in the Belt Drives.